Boost Quality Control: Your Trusted Partner for Cutting-Edge Material Testing Lab Providers

Wiki Article

From Raw Products to Last Products: The Duty of Product Screening Laboratories in Ensuring Quality and Reliability

Product screening laboratories play a critical function in this procedure, from evaluating raw products to examining the final products. By performing various tests, these laboratories make sure that the products made use of satisfy industry criteria and conform with laws. From checking the strength of metals to assessing the composition of plastics, material screening laboratories provide useful understandings to manufacturers and aid them deliver top notch products.Relevance of Material Screening in Quality Control

One of the main reasons that product screening is crucial for quality control is that it assists you determine whether the products meet the required standards and specifications. Via extensive testing, you can validate if the materials have the preferred mechanical, chemical, and physical buildings. This makes certain that your products will certainly do as desired and meet the expectations of your customers.

Furthermore, product testing assists you identify any potential security hazards related to your items. By evaluating for aspects such as flammability, toxicity, or electrical conductivity, you can make certain that your products conform with safety guidelines and requirements. This not just protects your consumers however also safeguards your credibility and minimizes the risk of responsibility.

Kinds Of Tests Carried Out by Product Testing Laboratories

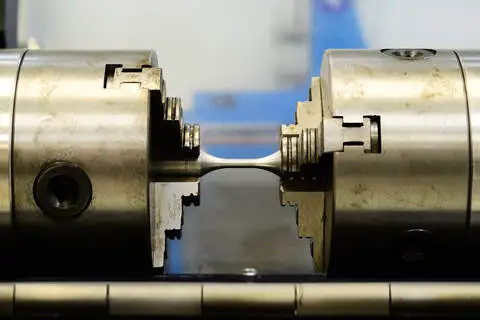

To guarantee quality and integrity, product testing laboratories perform a variety of examinations on basic materials and completed products. These examinations are important in identifying the physical, mechanical, chemical, and electrical residential or commercial properties of the materials present. One typical examination is the tensile examination, which determines the stamina and ductility of a material by subjecting it to stress till it damages. Another vital examination is solidity screening, which evaluates the product's resistance to imprint or damaging. Product screening laboratories also perform effect tests to examine a product's capability to hold up against unexpected shock or impact pressures. In enhancement, they execute fatigue examinations to assess the material's longevity and resistance to duplicated loading. Thermal conductivity tests are conducted to measure exactly how well a material carries out warm. Product testing labs perform deterioration examinations to establish a product's resistance to damage caused by chemical reactions with its setting. Finally, non-destructive screening methods such as radiographic or ultrasonic screening are used to discover internal imperfections or issues without damaging the material. By performing these tests, product testing labs make certain that the raw products and finished products satisfy the called for specs and criteria, guaranteeing quality and reliability in numerous sectors.Role of Product Screening in Ensuring Item Dependability

By analyzing the physical, mechanical, chemical, and electric properties of products, product screening makes certain the dependability of items. Product screening plays an essential duty in ensuring that the products you utilize or make are secure and trustworthy. Via a collection of strenuous tests, material screening research laboratories have the ability to identify any kind of potential weaknesses or flaws in the materials made use of in the manufacturing process. By doing so, they assist to stop failures and breakdowns that could result in expensive recalls, accidents, and even hurt to customers.

Product testing assists to figure out whether the materials utilized in the manufacturing of an item satisfy the needed standards and specifications. It assists to identify any kind of flaws or inconsistencies that can affect the performance or resilience of the final product. By subjecting materials to numerous examinations, such as tensile strength, solidity, deterioration resistance, or flammability, material testing makes sure that the materials used appropriate for their intended application and can withstand the problems they will certainly be exposed to.

In addition, material testing permits suppliers to evaluate the efficiency and dependability of their products under various ecological problems. By imitating real-world circumstances, such as extreme temperatures, moisture, or vibrations, product screening helps to identify any kind of possible weaknesses or vulnerabilities that can influence the product's performance or life expectancy. This permits manufacturers to make required renovations or modifications to make certain that their items meet the greatest standards of top quality and integrity.

Industry Specifications and Material Testing Compliance

Ensuring conformity with market criteria for material view screening is essential in keeping the top quality and reliability of items. These sector requirements function as guidelines that define the minimal needs and specs for screening products used in numerous markets. By adhering to these standards, producers can ensure that their products meet the required top quality and security standards.Material screening labs play a vital function in ensuring compliance with these sector requirements. These labs are outfitted with state-of-the-art tools and utilize experienced professionals who are well-versed in the testing treatments required for different products. They conduct a large range of tests, such as mechanical, chemical, and physical tests, to assess the residential properties and qualities of products.

Following sector requirements aids manufacturers fulfill customer assumptions and governing demands. It additionally assists in protecting against item failings and remembers, which can bring about financial losses and damages to the track record of the company. In addition, adherence to these requirements advertises reasonable competition amongst manufacturers, as it ensures that all products fulfill the very same high quality criteria.

Product screening compliance additionally plays a substantial duty in global trade. Many countries have their very own set of industry standards, and conformity with these standards is often a prerequisite for importing and exporting products. By making certain conformity, producers can expand their market reach and develop themselves as trusted providers in the global market.

Benefits of Partnering With a Product Screening Laboratory

When partnering with a product testing research laboratory, you can benefit from their experience and cutting edge equipment to ensure the high quality and reliability of your products. One of the crucial advantages is the accessibility to specialized expertise and experience that these research laboratories possess. Product screening labs use extremely knowledgeable specialists that have comprehensive understanding of various materials and screening methods - material testing lab. They can offer valuable understandings and recommendations to maximize redirected here your product layout and production processes.

Additionally, material testing research laboratories have progressed devices and technology that can precisely evaluate the residential or commercial properties and attributes of your products. They can carry out a variety of examinations, consisting of mechanical, chemical, and thermal examinations, to review the efficiency and toughness of your items. By partnering with a product screening research laboratory, you can make certain that your products fulfill or exceed sector requirements and regulative demands.

Another benefit of partnering with a product testing research laboratory is the capability to identify and address prospective issues prior to they come to be significant problems. With thorough screening and evaluation, these laboratories can detect any type of flaws, weak points, or variances in your materials. This enables you to make informed choices and take restorative activities to boost the quality and reliability of your items.

Conclusion

Finally, product screening laboratories play an important function in making sure the top quality and integrity of end products. By carrying out numerous examinations and sticking to sector criteria, these laboratories assist to identify any kind of potential defects or weaknesses in materials. Partnering with a product screening laboratory offers numerous advantages, including boosted item performance, client complete satisfaction, and compliance with laws. Relying on these labs to evaluate products throughout the production procedure is important for keeping high standards and delivering dependable items to customers.Product screening laboratories play a crucial role in this process, from evaluating raw products to reviewing the final products.To make certain top quality and integrity, product screening labs perform a range of tests on raw products and completed products. By conducting these examinations, product screening research laboratories make certain that the raw materials and finished items fulfill the required specifications and criteria, guaranteeing high quality and integrity in various markets.

By subjecting materials to various tests, such as tensile strength, firmness, rust resistance, or flammability, material screening makes certain that you could try here the materials utilized are suitable for their designated application and can withstand the problems they will certainly be subjected to. - material testing lab

Material screening laboratories use very competent professionals who have extensive expertise of various products and screening techniques.

Report this wiki page